Effect of Ultra-fast Cooling Process on Spheroidal Annealing of Bearing Steel

WANG Yonghong1, LI zhuang2, ZHANG Jinming3

(1. Hebei Yongyang Iron and Steel Corp., Yongnian 057150, China; 2. Shenyang Institute of Aeronautical Engineering, Shenyang 110034, China; 3. Shenyang Standard Component Research Institute, Shenyang 110141, China)

Abstract: The effects of ultra-fast cooling process on the microstructure and mechanical properties of bearing steel after hot rolling and then spheroidal annealing were investigated. The results show that it is obvious for spheroidal annealing structure the adopt ultra-fast cooling process. Spheroidal annealing structure is satisfactory and hardness increases with the decrease of final cooling temperature. The ultra-fast cooling process contributes to good spheroidal effect of pearlite.

Keywords: bearing steel; ultra-fast cooling process; spheroidal annealing; spheroidal pearlite

Bearings are widely used in mechanical products and engineering structures. Ball annealing must be made after hot rolling of bearing steel. Globalize the carbide completely. The carbide presents smaller spheres uniformly distributed in the ferrite matrix. Such an organization mechanical property well. The low of hypothermal sensitivity. The residual carbide is small and evenly distributed after tempering and quenching. Therefore bearing steel wear resistance, endurance bending strength and the impact toughness is high[1-2].

The rolling process has significant influence on GCr15 bearing steel[3]. In the producing of large section bearing steel bar. It is difficult to realize and control the difficulty of low temperature end rolling that the cooling problem. The super fast cooling after rolling of the bearing steel can cause the carbide to refining, disperse precipitation,disperse precipitation[4]. The uniform dispersion distribution of carbide in the original structure of GCr15 rolling bearing steel, It can improve its service life-span[5].

The author used rolled plates in the laboratory of northeastern university to replace bars. The process of rapid cooling and then slow cooling of bearing steel after high temperature deformation is adopted. It is used to control the mesh carbide precipitation out to get the small laminar pearlite tissue. The plate is spheroidizing annealed after rolling. The influence of super-fast cooling process on bearing steel carbide was studied.

1 experimental method

The materials used in the experiment are GCr15 bearing steel billet produced by a special steel plant in China. Its chemical composition (quality score, %) is:1.02C,0.32Si,0.34Mn,0.009P,0.003S,1.49Cr,0.07Ni,0.15Cu,0.02Mo,0.0017Ti,0.005Al.

The blank is heated to 1050 ~ 1100℃(1922-2012F) and heat preservation 1h in a box heating furnace. After the release, there are 3 rolls in 1000℃(1832F). The finishing roll is about 980℃(1796F). After finishing rolling, the sample size is 15mm×40mm×500mm steel plate. The total deformation is 53.1%. After rolling, the ultra-fast cooling. The cooling rate is controlled in 100-200℃/s(212-392F/s). After cooling, the plate is cooled to room temperature in the iron box with asbestos felt. Table 1 shows the parameters of the measured parameters in different cooling processes after the hot rolling of GCr15 bearing steel.

Tab.1 The process parameters of hot rolling test

| Process item No | Initial rolling temperature / ℃ | Finishing rolling temperature / ℃ | Cooling rate / (℃/s) | Finish cooling temperature / ℃ |

| 1# | 998 | 975 | 135 | 800 |

| 2# | 995 | 978 | 124 | 760 |

| 3# | 996 | 980 | 130 | 715 |

| 4# | 995 | 973 | 110 | 615 |

Heat the plate cooled to room temperature to 810℃(1490F) and hold 6h. Slow down to 650℃(1202F) with the furnace(The cooling speed is about0.05℃/s 0.12F/s), Then use the air cold. The fibrous tissue of the spheroidized annealing was observed. The influence of super fast cooling process on the performance of the bearing steel ball after annealing was analyzed.

2 experimental results and analysis

2.1 Microstructure and hardness

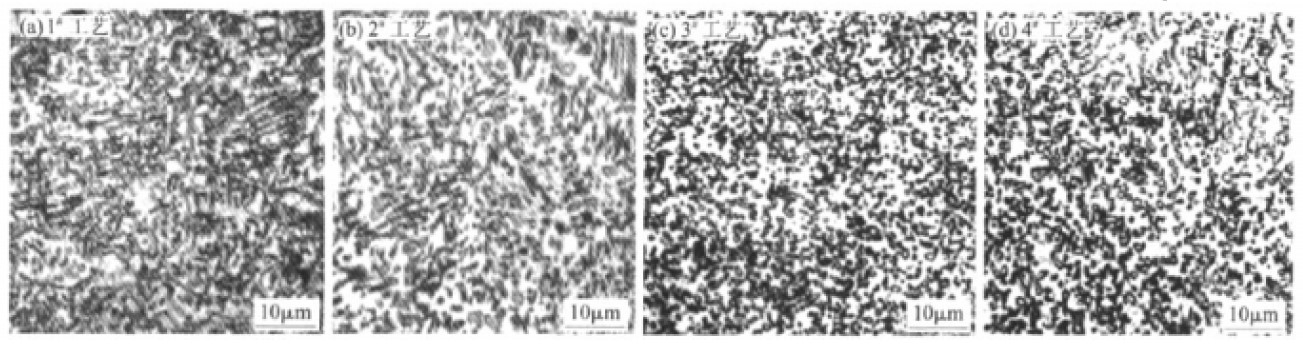

The bearing steel is Ultra-Fast Cooling to room temperature. The microstructure is obtained after spheroidization annealing is shown in figure 1. As you can see, the spheroidized annealing. The carbonates have been spherified to varying degrees. The test sample of spheroidizing annealing after cooling process 1# 2# to room temperature. The tissue can see a small amount of fine grained pearlite. Spherification is not uniform, As shown in figure 1 (a) (b). After the end cold temperature of the ultra-fast cold is reduced to 715℃(1319F). The obvious laminar pearlite disappeared in spheroidized annealing tissue. The carbide has a smaller globule and dot evenly distributed on the ferrite. The spheroidized pearlite tissues were obtained uniformly. As shown in figure 1 (a) (b).

Fig.1 Spheroidal annealing structure after different cooling processes

After the spherification is annealed the average hardness of 1s ~ 4s samples was 169, 187, 205 and 217HB respectively. Be able to see, The GCr15 bearing steel is in the process of ultra-fast cooling. As the final cooling temperature decreases. Hardness increases trend. The hardness value is highest in process 4 #.

2.2 Ultra-fast cooling and fine pearlite

The bearing steel is super-fast cooling after high temperature hot rolling. The temperature of the steel surface is quickly cold to a little bit higher the martensite point (Ms) and immediately stop the forced cooling process. Subsequently, Too cold of steel surface temperature, his internal heat is transmitted outward, the surface temperature can be returned to the temperature range of the pearlite. It is slowly cooled with the inner austenite. The surface of steel is super-fast cooling and temperature recovery process. Both are completed in the incubation period of the cooled austenite transformation curve. The whole process does not produce phase transitions. And the plate interior depends on the surface of the greater temperature gap. The cooling speed is also relatively high. The cooling rate can be achieved to suppress the network carbide precipitation.

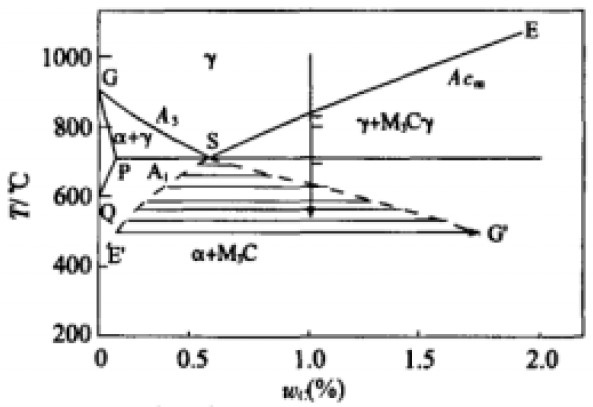

Fig.2 Quasi-equilibrium diagram of Fe-C

GCr15 Bearing steel under ultra-fast cooling conditions. Network carbide precipitation was inhibited. It obtained the schematic diagram of small pearlite organization. See figure 2. The GSE line above is the austenite region, in the right of GES line is a proeutectoid of the secondary carbides. Be able to see,the GCr15 bearing steel of 1.02% the carbon content that it’s austenite is slowly cooling. Along the ES line separate out proeutectic secondary carbide. As the secondary carbide precipitates out. The carbon concentration of austenite is gradually close to the eutectoid component (S). In the end, the austenite with eutectoid is transformed into pearlite under A1 point. If A3 and ACm are extended to below the A1 temperature respectively. The line SE’ indicates that the limited of the saturation solubility of the supercooled austenite. It is the limit of saturation solubility of ferrite in the cooled austenite is studied.

This is shown in figure 2. The 102% GCr15 bearing steel is super-fast cooling in austenitic area, fast through the secondary carbide,then slow down to cool down. In the case of cold austenitic, the period of retention of the secondary carbide precipitation was reduced. It can’t be completely suppressed the precipitation of the proeutectoid secondary carbide. But the secondary carbide precipitation decreases. It also shortened the time it had gathered in the crystal world. Thus the network secondary carbide level decreased. It also increases the cooling. The perlite transition temperature decreases. In the pearlite transform region, in a slow, slow cooling process, You get tiny pearlitic tissues.

As the final cooling temperature continues to decrease. Reduced the conversion temperature. The concentration difference in the shaded region becomes larger. Before the pearlite transform, The precipitation and accumulation of proeutectoid secondary carbides are rarely grow up. The cellular precipitation of the proeutectoid secondary carbide was eliminated. The noneutectoid components of austenite are cold to the shadow zone. This slow cooling process. The ferrite and cementite will be precipitated simultaneously. This transition process and transformation products are similar to eutectoid transformation. But the ratio between the ferrite and the cementite is not determined In the transformation product. It’s going to change with the carbon content of the austenite. Therefore, it is called pseudoeutectoid transformation. The small pseudocotectoid organization of inhibit mesh carbide precipitation was obtained.

Therefore, the process 1 # 2 # cooled to room temperature and there was a small amount of fine flaky pearlite in the tissue. As the ultra-fast final cooling temperature decreases. Process 3 # 4 # cooled at room temperature, the thin slice pearlite disappeared. The spherification of pearlite is better. By the powerful strength of the super-fast cooling process. The inner and outer cooling speed of steel is enhanced. The purpose of inhibition of network carbide precipitation was achieved.

2.3 Spherification of the laminar pearlite

In the ultra-fast cooling process,The final cooling temperature is too high. The spheroidized annealed that the organization is not uniform. The crystal boundary has a network structure. As the final cooling temperature decreases. After the spheroidized annealing is get a uniform structure.

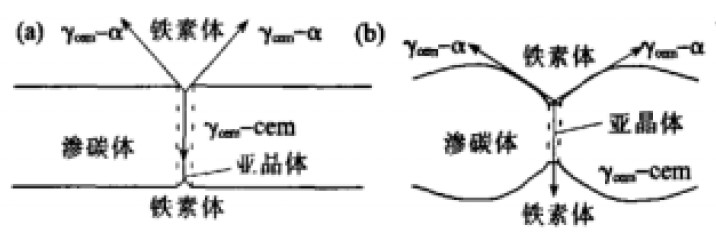

Spheroidized pearlite tissues, it is obtained through the spherification of carburized body in the flaky pearlite. In the process of spheroidizing annealing. Heat it up to the higher temperature of below A1 and keep it warm for a long time. The lamellar pearlite can spontaneously transform into granule pearlite. This is due to the high surface energy of the laminated pearlite. The energy of the system decreased after Transform to granule pearlite. It’s a spontaneous process. Figure 3 is a schematic diagram of spheroidization mechanism of laminar pearlite[6].

Fig.3 The spheroidization mechanics graphics of lamellar pearlite

The lamellar pearlite is composed of carbonic and ferrite films. There is a dislocation in the carburized film. It can form the sub-boundary or high dislocation density region. The contact between the ferrite and the carburitic sub-boundary have formed a grooved groove. As shown in figure 3 (a). The cementite on both sides of the pit is compared with the carburized body of the plane. It has a smaller radius of curvature. The austenitic body with the groove wall has a higher solubility. Will cause diffusion in austenite,The form of carburized carbon was precipitated in the nearby planar carburization

In order to keep the balance,The sharp angle of the cementite on both sides of the groove will gradually dissolve. It makes the radius of curvature increases. In this way damages the phase boundary tension (gamma-a and gamma-cem) here. In order to maintain that balance. The groove will be deepened by the further dissolution of the carburized body. As shown in figure 3 (b)

In the original tissues are smaller space between the pearlitic interlaminae. It is easier to dissolve in the heating process than the coarse-plate pearlite, dissolution and formation, small and granular carbide particles distributed uniformly. These granular carbide are small and have a large dispersion degree. It causes the carbon atoms of the austenite to spread as a short range. The most favorable conditions for atomic migration are caused. Therefore, we can accelerate the spherification of pearlite.

So in the experiment, As the final cooling temperature of ultra-fast cooling is reduced from 800℃ to 715℃ (1472F-1319F). The spacing of the pearlite laminar in the original tissue is decreased. The crystal boundary of network secondary carbide separate out is reduced and eventually disappeared. Therefore, a uniform spherification pearlite organization was obtained. Moreover, the final cooling temperature decreases with the hot rolling. Enhance the overcooling. The position error density of pearlite and the increase of the number of subgrain. It also promotes the progress of spherification of pearlite.

3 conclusion

(1) The bearing steel cools quickly after hot rolling。After spherification and annealing. The carbonates have been spherified in varying degrees.

(2) Under super fast cooling conditions. As the final cooling temperature decreases. The bearing steel spheroidization after annealing is uniform microstructure. hardness were increased,

(3) The superfast cooling has inhibited the precipitation of the bearing steel network carbide. As the final cooling temperature decreases after hot rolling. Increase of subcoold temperature. The number of dislocation density in pearlite and the number of subboundary is increased. It helps the pearlite to achieve better spherification.

References:

[1] Brien O J M, Hosford W F. Spheroidization cycles for medium carbon steels [J]. Metal. Master. Trans. 2002. A33(4): 1255-1261.

[2] 黄平惠,刘厚权,吴贵平. 电加热辊底式连续退火炉热处理滚珠钢的生产实践 [J]. 热加工工艺,2008.37(6): 84-86.

[3] 叶慧丽,李国忠,惠荣等. 轧制工艺对GCr15球化退火的影响 [J]. 热加工工艺,2007.36(6): 30-55.

[4] 王国栋. 新一代TMCP的实践和工业应用举例 [J]. 上海金属,2007.30:1-4.

[5] Wang Y, Yan F G, Wang P. Finite element analysis of precision hard cutting using different cutting edge preparation [J]. Applied mechanics and materials, 2008.10-12: 353-358.

[6] 刘云旭. 金属热处理原理 [M]. 北京:机械工业出版社,1981.45.H.